- The Concrete Corner

- Posts

- The Concrete Corner - April

The Concrete Corner - April

Build It, Store Smarter, Learn More: Spring Forward with The Concrete Corner

Welcome to The Concrete Corner! This monthly newsletter highlights Ozark Ready Mix, Fischer Concrete Services, and all things concrete and concrete products. In this newsletter, you'll get a behind-the-scenes look at our concrete operations, meet outstanding individuals and businesses, and stay current on concrete news and trends throughout the Midwest and the United States. Hopefully, this will be mildly informative, and a little entertaining. However, just like the ready-mix concrete business, I offer no guarantees!

In this month’s The Concrete Corner newsletter presented by AT&S Storage:

Dual plant foundation pour

Retrofitted shipping containers

White-collar shortage

Aggregates galore

Hot Concrete

Premier Foundations

Premier Foundations is a Shawnee, Kansas family-owned and operated foundation company that has been serving developers, contractors, builders, and private homeowners throughout the Greater Kansas City Metro area for many years. To ensure timely delivery for this project, we efficiently dispatched concrete trucks from both our KC, MO Bannister plant and our Olathe, KS plant. By providing reliable service, Ozark Ready Mix is proud to support Premier Foundations in building strong foundations for new homes. Their dedication to quality and customer service perfectly matches our values, and we look forward to partnering with them on many more successful projects in the years to come.

KC, MO trucks at the pump

Coordinating and truck placement with little space

American Trailer & Storage

For the past few years, Ozark Ready Mix and Fischer Concrete have been utilizing retrofitted shipping containers from American Trailer & Storage for various purposes. These modified containers have proven to be a fantastic solution to our needs. AT&S and their team including Ross Fogel and Robert Ray have worked closely with us to plan, design, and build each container to our exact specifications, transforming them into functional batch houses, driver lounges, and offices with bathrooms.

Batch house specifically built to follow this portable plant from job to job

Added hidden door for extra security

These customized containers offer a wealth of features that make them ideal for our operations. Standard features for us include 100-amp electrical system, LED lights, ample electrical outlets, a secure entry door with window, climate control through HVAC units, additional windows for natural light, durable easy-to-clean flooring, and insulated walls for year-round comfort.

New batch house container at our KC, MO Bannister location

Bannister batch house close to completion

Contractors, are you looking for a cost-effective way to protect your valuable equipment and materials from theft and the elements? Look no further than containers from AT&S. Their durable steel construction and hidden security doors (added feature) transform them into a secure fortress, safeguarding your tools and supplies from theft, vandalism, and harsh weather. This keeps your equipment in top condition and protects your bottom line.

Combinations of functionality and adaptability make retrofitted storage containers a cost-effective and versatile option for ready-mix concrete suppliers like ourselves. Not only that, AT&S boasts a swift production turnaround, often delivering these containers ahead of schedule, minimizing downtime, and getting our operations up and running even faster!

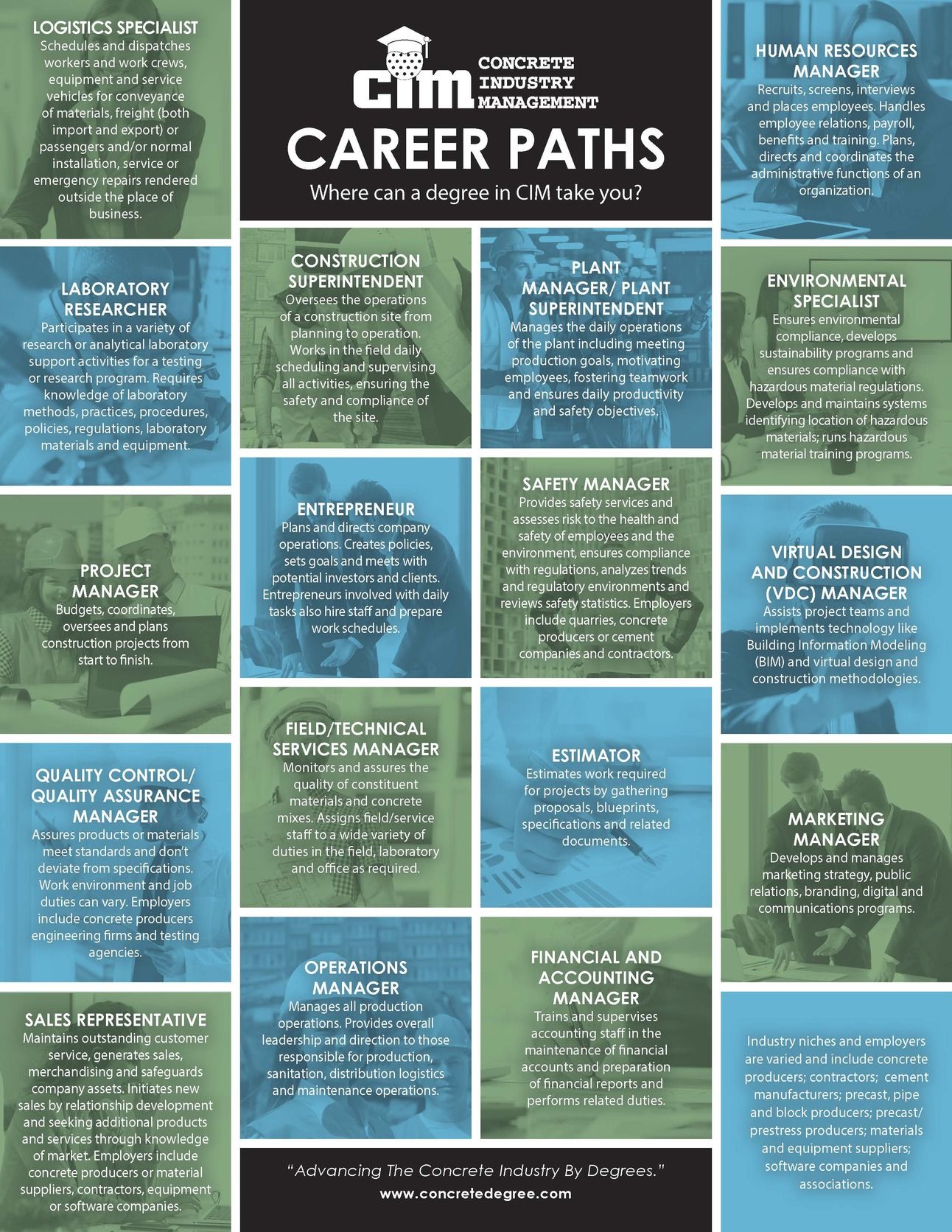

Concrete Industry Management Degrees

The construction industry faces a double whammy: labor shortages and a lack of skilled workers. This is stalling growth and limiting high-paying job creation. Numerous national, state, and local associations within our industry have urged policymakers to prioritize construction education. The ready-mix concrete industry isn’t “sexy” for most college graduates. We are not a siren song compared to the allure of tech giants or architectural and engineering firms. Recent graduates are often drawn to the flashy world of tech startups or the prestige of architectural and engineering firms. The ready-mix concrete industry, while crucial for building our communities, doesn't always capture their attention in the same way.

Bridging the Gap: Concrete Industry Management Programs

The ready-mix concrete industry thrives on practical knowledge, which recent graduates might not yet possess. Internship opportunities can also be limited. Enter Concrete Industry Management (CIM) programs. Offered at select universities, these specialized degrees can be gateways to success in our industry.

What CIM programs offer:

Job-Ready Graduates: Nearly 100% placement rate ensures a smooth transition into the workforce.

Financial Support: Scholarships and financial aid opportunities ease the burden of college costs.

Holistic Education: Develop a strong foundation in business management, finance, marketing, and law, with a business minor that is required.

Hands-on Learning: Gain practical experience through internships and work with cutting-edge technology.

Industry Network: Build connections with industry leaders through programs, events, and a growing alumni network.

Career Advancement: Diverse career paths with opportunities for rapid promotion into management positions.

Advanced Degrees: Pursue further education with available Master’s and Executive MBA programs.

Where are these programs?

Concrete Industry Management programs benefit the ready-mix concrete industry by creating a more skilled workforce. Graduates can hit the ground running with their knowledge of concrete production and industry-specific business practices. This expertise leads to increased efficiency, cost savings, and innovation in areas like concrete mixes and production techniques. CIM programs also help address the industry’s labor shortage by providing a pipeline of qualified candidates for leadership roles. Overall, these programs are a win-win for both graduates and the ready-mix concrete industry.

While my alma mater, the University of Missouri, doesn’t currently offer a dedicated CIM program, it would be awesome to see them develop one in the future. They already have strong business and engineering programs, so it seems like a natural fit…

Piles of Rock & Sand

At Ozark Ready Mix, we understand the importance of high-quality materials for every project. That’s why we source our rock and sand aggregates from trusted partners throughout Kansas and Missouri (More on them in future newsletters). We prioritize optimizing travel time and haul rates by matching aggregate sources to the closest plant location. This ensures efficient delivery without compromising on the quality of the materials our customers rely on.

Larry Wagner keeping our trap rock pile full

Rear view of the end dump

Our dedicated material transportation team plays a vital role in keeping our plants running smoothly. On any given day, you might see experienced material drivers like Larry Wagner and Dee Whearty behind the wheel of our end dump trucks. They, along with other Ozark Transportation and Fischer Transportation team members, make up the backbone of our hauling operations. For materials sourced from further distances, for example at our Chillicothe, Trenton, and Bethany, MO plants we rely on the expertise of trusted third-party haulers. This ensures a seamless supply chain and consistent delivery of the quality aggregates we need for our concrete.

Dee Whearty filling the sand pile

More sand!

Did you know…Pouring concrete during hot weather can be tricky because high ambient temperatures accelerate the setting process. ACI 305 “Hot Weather Concreting” defines hot weather as any combination of the following conditions that tend to impair the quality of the freshly mixed or hardened concrete:

High ambient temperature

High concrete temperature

Low relative humidity

Wind speed

Solar radiation

Concrete poured in hot weather is susceptible to:

Increased water demand (bad for the concrete)

Increased rate of slump loss (bad for our customers)

Increased rate of setting (bad for our customers)

Increased tendency for plastic-shrinkage cracking (bad for our customers)

Increased difficulty in controlling entrained air content (bad for the concrete)

Decreased 28-day and later strengths (bad for our customers)

Increased tendency for thermal cracking (bad for the concrete)

Concrete without proper planning & QC in place that “got away” from a contractor

How do we handle pouring concrete in hot weather?

Planning is Key:

Early Morning Pours: The ideal scenario is to pour concrete before sunrise when temperatures are coolest. However, this isn’t always feasible.

Cooling the Mix:

Chilled Water: Concrete plants can utilize chillers to lower the mixing water temperature, keeping the overall concrete mix cooler.

Ice on Demand: When chillers aren’t available, adding 20-40 lbs of ice per cubic yard of concrete with a conveyor helps cool the mix during transport.

Combined Approach: Sometimes, both chillers and ice are used for maximum cooling effect.

Chemical Control:

Type D Admixtures: These admixtures slow down the hydration process (cement’s reaction with water) which generates heat. This helps prevent the concrete from setting too quickly in hot weather.

The summer heat doesn’t have to be a headache for producers or contractors. By strategically using chilled water, ice, and Type D admixtures, we can keep the concrete cool and setting at the right pace.

See you next month for another peek behind the concrete curtain!

Kenny Jackson!